RESEARCH

IS IN OUR GENES

RESEARCH

IS IN OUR GENES

LAVOCE speakers are based on our relentless research in sound quality, Italian technical excellence, product reliability and consistency of electro-acoustic performances, combined with distinctive design elegance. Always being a step ahead!

INNOVATION-DRIVEN

ATTITUDE

INNOVATION-DRIVEN

ATTITUDE

Our team is constantly focused on innovation in every aspect, such as testing new raw materials, design geometries or production processes. We also work with university research centers and we share and exchange information with the professional scientific communities.

MEETING UNIQUE

SPECIFICATONS

MEETING UNIQUE

SPECIFICATONS

In OEM/ODM solutions, after defining the parameters and basic requirements, our engineers work closely with our partners to identify the most suitable guidelines of their projects. We are able to produce a speaker to the exact desirable specifications, through customization of Lavoce models or by developing unique products, tailor-made to suit our partner’s needs.

Constant research to be always a step ahead

Continuous innovation at 360

° (materials, design, technology, production processes)Modern R&D Labs with the latest hardware/software tools and facilities

Ability to meet the unique specifications of ODM/OEM projects

Rigorous design validation processes

Excellent measurement and control tools (Klippel R&D System)

Accurate and extensive tests (reliability test, drop test, etc.)

-

DESIGN

Our team of engineers boasts over 30 years of experience in HF and LF driver design and our R&D center is equipped with state-of-the-art hardware and software facilities for simulation, electro-acoustic and mechanic design and loudspeakers measurement.

All LA...Our team of engineers boasts over 30 years of experience in HF and LF driver design and our R&D center is equipped with state-of-the-art hardware and software facilities for simulation, electro-acoustic and mechanic design and loudspeakers measurement.

All LAVOCE loudspeakers, both top of range and entry level, are subjected to our rigorous design validation process based on Finite Element Modeling techniques (FEM and FEA) and electro-acoustic plus mechanical simulations of:

– Sound pressure level at various points in space

– Modal analysis of the radiant sections

– Non-linearity suspension Analysis

and all the other critical aspects of the loudspeaker design.The use of 3D-CAD systems for Mechanical Design ensures then an efficient development of the project up to the execution of the final technical drawings.

Advanced measurement and analysis systems complete the design cycle, allowing an accurate examination of the transducers’ static and dynamic performance.read more -

Our team of engineers boasts over 30 years of experience in HF and LF driver design and our R&D center is equipped with state-of-the-art hardware and software facilities for simulation, electro-acoustic and mechanic design and loudspeakers measurement.

All LAVOCE loudspeakers, both top of range and entry level, are subjected to our rigorous design validation process based on Finite Element Modeling techniques (FEM and FEA) and electro-acoustic plus mechanical simulations of:

– Sound pressure level at various points in space

– Modal analysis of the radiant sections

– Non-linearity suspension Analysis

and all the other critical aspects of the loudspeaker design.The use of 3D-CAD systems for Mechanical Design ensures then an efficient development of the project up to the execution of the final technical drawings.

Advanced measurement and analysis systems complete the design cycle, allowing an accurate examination of the transducers’ static and dynamic performance.

-

PROTOTYPING

We use rapid prototyping techniques, minimizing the time required to acquire the necessary parts, which are nearly identical to final mass production parts.

LaVoce R&D team checks and measures prototypes using absolutely excellent tools:

– KLIPPEL R&#...We use rapid prototyping techniques, minimizing the time required to acquire the necessary parts, which are nearly identical to final mass production parts.

LaVoce R&D team checks and measures prototypes using absolutely excellent tools:

– KLIPPEL R&D SYSTEM and Distortion Analyzer, to verify LPM and LSI parameters and frequency response, to check and validate motor design, suspension geometries and voice coil position alignment.

– Klippel Scanning Vibrometer, to define and optimize the behavior of mobile parts.

– Klippel Power Monitor 8, to verify long term power handling, thermal dissipation and reliability.

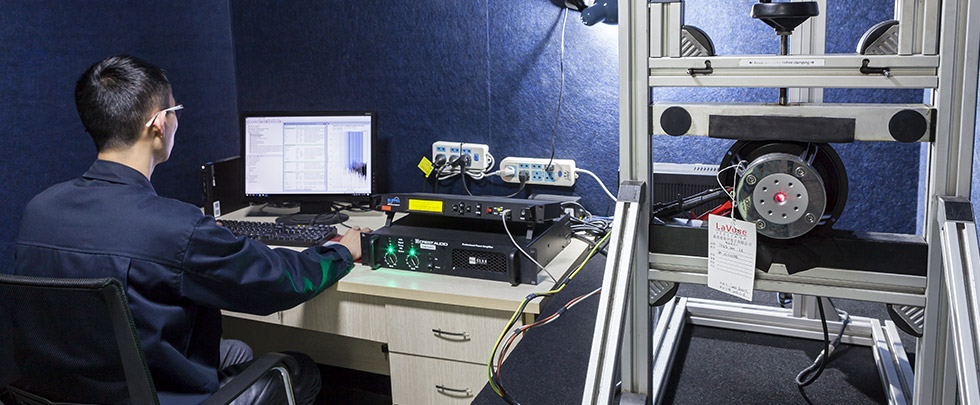

Our anechoic room provides a reflection-free environment, ideal for precision measurement of the main transducer physical properties, frequency response and sound pressure level.read more -

We use rapid prototyping techniques, minimizing the time required to acquire the necessary parts, which are nearly identical to final mass production parts.

LaVoce R&D team checks and measures prototypes using absolutely excellent tools:

– KLIPPEL R&D SYSTEM and Distortion Analyzer, to verify LPM and LSI parameters and frequency response, to check and validate motor design, suspension geometries and voice coil position alignment.

– Klippel Scanning Vibrometer, to define and optimize the behavior of mobile parts.

– Klippel Power Monitor 8, to verify long term power handling, thermal dissipation and reliability.

Our anechoic room provides a reflection-free environment, ideal for precision measurement of the main transducer physical properties, frequency response and sound pressure level.

-

VALIDATION

Our R&D team starts the assessment and validation process until the final prototypes satisfy the project requirements.

All LAVOCE and OEM drivers are tested in our dedicated state-of-the-art validation department through Klippel R&D and are validated by perform...Our R&D team starts the assessment and validation process until the final prototypes satisfy the project requirements.

All LAVOCE and OEM drivers are tested in our dedicated state-of-the-art validation department through Klippel R&D and are validated by performing an AES power test, as well as a continuous musical life test, in our fully automated and completely monitored power test container equipped with Klippel Power Monitor 8. Approved prototypes are then subjected to listening tests with our acoustic engineers and experienced audiophiles, who contribute to the final sound definition.read more -

Our R&D team starts the assessment and validation process until the final prototypes satisfy the project requirements.

All LAVOCE and OEM drivers are tested in our dedicated state-of-the-art validation department through Klippel R&D and are validated by performing an AES power test, as well as a continuous musical life test, in our fully automated and completely monitored power test container equipped with Klippel Power Monitor 8. Approved prototypes are then subjected to listening tests with our acoustic engineers and experienced audiophiles, who contribute to the final sound definition.

-

SAMPLING

All samples are assembled with finalized parts, the same as mass production would use, for ensuring accuracy of our electro-acoustic measurements, life tests and power tests.

Through specific equipment we perform reliability tests such as:

– The...All samples are assembled with finalized parts, the same as mass production would use, for ensuring accuracy of our electro-acoustic measurements, life tests and power tests.

Through specific equipment we perform reliability tests such as:

– Thermal Shock tests

– Constant Thermal/Temperature tests

– Humidity tests

– Saltwater Spray testsMoreover we apply a series of drop tests according to the unique mechanical properties of the project, with various height points to simulate real-world outcomes.

The same drop test techniques are used on the packaging materials, essential in protecting the products during transportation.

When all project tests and validation are successfully completed, our team defines mass production cycles: assembly procedures, process variables and their measurements, Quality Control plans.

Only after this stage Lavoce R&D team releases the project to our production facility for the beginning of new product mass production.read more -

All samples are assembled with finalized parts, the same as mass production would use, for ensuring accuracy of our electro-acoustic measurements, life tests and power tests.

Through specific equipment we perform reliability tests such as:

– Thermal Shock tests

– Constant Thermal/Temperature tests

– Humidity tests

– Saltwater Spray testsMoreover we apply a series of drop tests according to the unique mechanical properties of the project, with various height points to simulate real-world outcomes.

The same drop test techniques are used on the packaging materials, essential in protecting the products during transportation.

When all project tests and validation are successfully completed, our team defines mass production cycles: assembly procedures, process variables and their measurements, Quality Control plans.

Only after this stage Lavoce R&D team releases the project to our production facility for the beginning of new product mass production.

Privacy OverviewThis website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Strictly Necessary CookiesStrictly Necessary Cookie should be enabled at all times so that we can save your preferences for cookie settings.

If you disable this cookie, we will not be able to save your preferences. This means that every time you visit this website you will need to enable or disable cookies again.

3rd Party CookiesThis website uses Google Analytics to collect anonymous information such as the number of visitors to the site, and the most popular pages.

Keeping this cookie enabled helps us to improve our website.

Please enable Strictly Necessary Cookies first so that we can save your preferences!